American Locomotive Company (ALCO) : The History

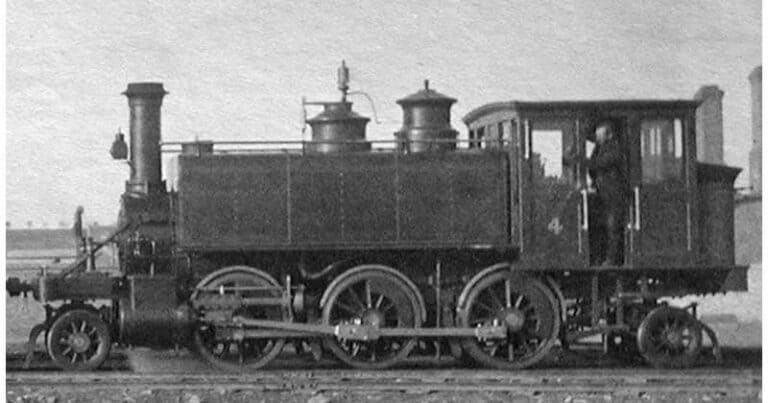

After establishing itself as a leading producer during the steam age, perhaps no other locomotive manufacturer was as poised to take advantage of the transition from steam power to diesel as the American Locomotive Company (ALCO). The company began operation in 1901 as the result of a merger by seven smaller locomotive manufacturers with the Schenectady Locomotive Engine Manufactory at a pivotal time in the railroad industry.

At the turn of the 20th century, the industry was within decades of a massive transition that would leave some locomotive manufacturers unable to compete as the popularity of new diesel propulsion took over. Perhaps because ALCO brought together the minds and resources of seven important manufacturers, it could be argued that the result was more than the sum of their parts. Joining the Schenectady Locomotive Engine Manufactory in Schenectady, NY, the seven companies that merged were:

- Brooks Locomotive Works in Dunkirk, NY

- Cooke Locomotive & Machine Works in Paterson, NJ

- Dickson Manufacturing Company in Scranton, PA

- Manchester Locomotive Works in Manchester, NH

- Pittsburgh Locomotive & Car Works in Pittsburgh, PA

- Rhode Island Locomotive Works in Providence, RI

- Richmond Locomotive Works in Richmond, VA

BUILDING AND MOVING AHEAD

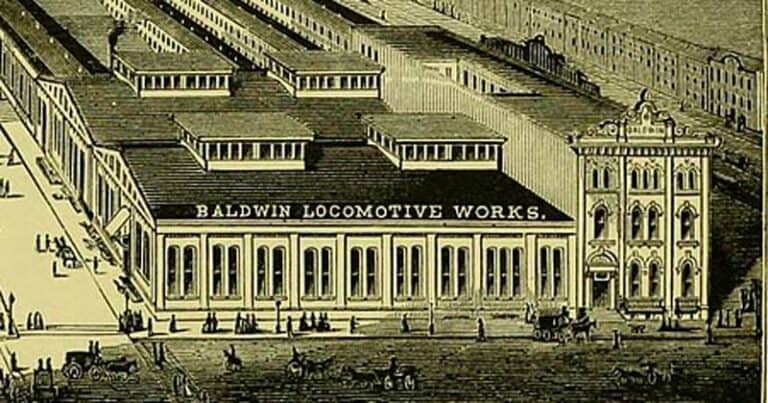

ALCO’s headquarters were in Schenectady with Samuel Callaway, who left the presidency of the New York Central Railroad, at the helm of the newly formed corporation. Upon Callaway’s death in 1904, Albert Pitkin became president of ALCO. In 1905, ALCO purchased Rogers Locomotive Works in Paterson, New Jersey, thus acquiring the number two locomotive manufacturer in the U.S.

With these vast resources and customer base, ALCO quickly became the number two manufacturer of steam locomotives and, during their company’s history, produced over 75,000 engines, including steam and diesel-powered models. Many of the nation’s most important railroad companies purchased ALCO products, including the New York Central Railroad and the Union Pacific Railroad.

ALCO’s design and engineering expertise led to the building of one of the largest locomotives ever made—the Union Pacific’s Big Boy, a 4-8-8-4. They also built the fastest American engines—the Class A Atlantic and Class F7 Hudson used on Milwaukee Road’s Twin Cities Hiawatha route.

While steam-powered locomotives marked their early years, and a successful foray into diesel power was a hallmark of their later years, ALCO also manufactured some electric locomotives for railway lines in Oregon, including a 60-ton, center-cab electric freight motor model beginning in 1912.

As many of their contemporaries struggled with seeing the future of diesel-powered locomotive engines, ALCO was an early believer in the coming change. They partnered with General Electric for electrical equipment and expertise and Ingersoll-Rand for similar assistance with diesel engines. The result was the first diesel/electric switch engine to be commercially successful. The Central Railroad of New Jersey was the first purchaser, with orders from the Long Island Rail Road and the Chicago and North Western Railway not far behind.

To expand their offers and maximize profits, ALCO purchased McIntosh & Seymour Diesel Engine Company in 1929 to have an in-house supplier for diesel engines. They also maintained a consortium partnership with GE on electrical equipment. The foresight helped to make ALCO an early entry in the manufacturing market for diesel/electric switch engines in the U.S. from the early to mid-1930s.

Even after embracing diesel technology earlier than most of their competitors in the locomotive industry, their lead was short-lived. Over the next decade, ALCO fell behind and began to lose precious market share to General Electric and GM’s Electro-Motive Division (EMD). That slide continued until the mid-1940s when ALCO was in control of only just over one-quarter of the diesel locomotive market.

What success that remained could largely be attributed to their RS locomotives, which contained the first modern road-switcher.

THE WAR EFFORT

Just as the American Locomotive Company started to gain steam (pun intended) in the development of larger diesel locomotives, the U.S. entry into WWII resulted in their development of diesel locomotive technology being frozen. For the war effort, ALCO was designated to focus on the construction of diesel switching locomotives, a small number of dual service engines, their new road-switcher locomotives, and the tried-and-true steam designs. EMD, their strong competitor, was given the task of mainline diesel road freight production. The loss of momentum for ALCO during this time and the subsequent additional time developing diesel locomotives by their competitor would be a contributing factor to the eventual demise of the American Locomotive Company.

Like many other locomotive and machine works, ALCO also pivoted to assist the war effort with the construction of tanks and tank guns at the Schenectady facility. At one point, 6,200 people were employed in these efforts.

ALCO’s products also played a significant role in battle strategy in the war theater. When the Luftwaffe attempted to blockade Allied supplies from reaching the Soviet Union, the U.S. was able to bring ALCO’s RSD-1, a six-axle, six-traction motor version of the lighter RS-1 to the area. They extended the Trans-Iranian Railway to the Soviet Union to circumvent the blockade and allow the Soviet war efforts to continue.

STRUGGLING TO KEEP PACE

Changes in the domestic and export markets increased competition and knocked ALCO from its second-place position as a diesel manufacturer, right behind EMD. In 1956, GE entered the export market and in 1960 the introduction of its newest locomotive model marked its rise in production and delivery.

ALCO continued to innovate, including the production of the first AC/DC transmission, but it could not keep pace. Now in third place behind EMD and GE, ALCO struggled. Without earning sufficient profits to compete, their products suffered from reliability issues, which only worsened the situation.

The India and Pakistan markets, which had been big consumers of the company for many years, also developed problems. In the fall of 1968, the company canceled an order with Pakistan for 60 locomotives after delays by the Pakistani government increased the order’s cost. Production was dropping from an average of 200 engines produced per year to just 70 locomotives in 1968. Layoffs followed and by the beginning of 1969, there were only 1,100 employees left at the plant. Two final locomotives, both T-6 switchers for Newburgh & South Shore Railroad, were the last products to leave ALCO’s plant. ALCO’s designs were sold to Montreal Locomotive Works (MLW) and the plant was closed.

MLW continued manufacturing of the ALCO-designed locomotives, and the diesel engine business was sold in 1970 to White Motor company. After some additional sales of the diesel engine division, the designs came to rest at the Fairbanks-Morse company and ALCO engines are still being produced by them today.

The plant in Schenectady was demolished in 2019 and is now the site of an industrial park. Despite their end, ALCO’s place in the history of steam and diesel locomotive manufacturing remains significant. Several steam engines are preserved around North America, and operational locomotives built by ALCO include:

- Union Pacific 844 – Owned by Nevada State Railroad Museum in Boulder City, Nevada, it is the only operational locomotive of its kind. It offers periodic excursions through the Nevada Southern Railroad Museum. It has also been featured extensively in films and documentaries.

- Union Pacific Big Boy 4014 – After significant restoration work, the Big Boy took to the rails again in May of 2019. In 2022, officials at Union Pacific announced a tour through many U.S. cities.

- Milwaukee Road 261 – Since its restoration in 2012, this locomotive has made several excursions over the last decade.

- Soo Line 1033 – After retirement from service in 1954, the Soo Line 1033 was restored to service in 1996 and operates occasionally on the railroads of the Upper Midwest.

Other locomotives preserved across the world include an ALCO 2-8-2, built in 1945 at the National Railway Museum in Entroncamento, Portugal, and an ALCO 2-10-0 at the Zduńska Wola Railway Museum, Poland.

The rise and fall of ALCO as an American manufacturer and significant player in the expansion of the United States cannot be denied. As more organizations recognize and preserve the heritage of domestic railways, ALCO’s importance is unquestionable.

A longtime railfan, Bob enjoys the research that goes into his articles. He is knowledgeable on many railroad topics and enjoys learning about new topics. You can get a hold of Bob at his email link below.